The first step in the iSustain industrial recycling services process is an in-person review of your business’ facilities. Drawing upon decades of experience in the recycling industry, our team of experts will evaluate your buildings and equipment to determine your current waste-handling capabilities and what might be needed to enhance them.

Next, our team focuses their attention on your current waste disposal processes. As part of our industrial recycling services, we review and document every step of the process: from who is responsible, to how it moves and where it goes.

Recycling has evolved, so your waste stream can too. After reviewing your current facilities and processes, iSustain takes a look at the types of waste your business is generating and the options that are available for recycling. Our industrial recycling services are designed to uncover new recycling opportunities, with a strong possibility that much of your waste can be recycled.

These days, “going green” doesn’t mean spending a lot of money and seeing no return. In fact, a zero-waste approach can actually save you money. Following our assessment of your operation, iSustain will review your total waste stream costs, including labor, fees, and the incremental costs associated with generating more waste – and identify key areas where costs can be reserved. We will present our findings in a straightforward report you can evaluate.

At iSustain, our goal is to develop creative industrial recycling services that adapt to an ever-changing world. Following our audit of your business’ waste management practices, we will develop a custom, data-driven proposal aimed at reducing the amount you spend on waste removal, diverting as much waste as possible from landfills, and improving your sustainability objectives.

We provide everything you need: from Gaylord boxes and baling wire to the balers themselves. We even harness the power of AI to track and predict the optimal time to collect your waste, saving you money.

With minimum-recycled content laws becoming ever-prevalent, plastic waste is in increasingly high demand. Vendors across the nation are looking for your plastic waste. Our network of cutting-edge solution partners help keep your materials moving.

With over 75 years of collective experience, iSustain knows what works and what doesn’t. We’ve seen trends come and go and continue to stay at the forefront of the industrial recycling services industry.

Included in your proposal is a complete, turnkey solution to your waste stream issues. Tailored to your business, iSustain will oversee every step of the process. From arranging pickups to keeping things running on schedule, iSustain is with you every step of the way.

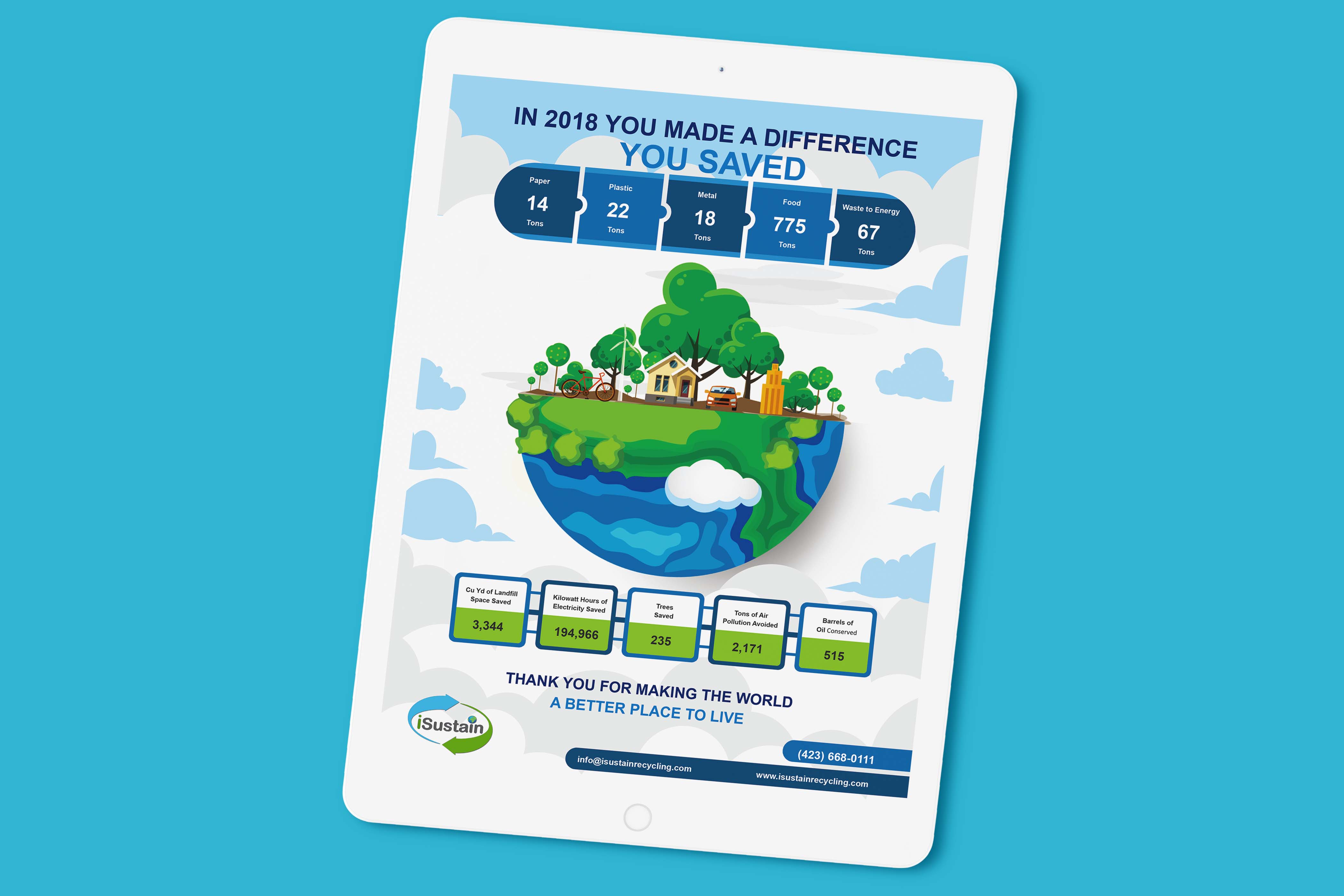

In addition to full logistical support, iSustain provides monthly financial impact reports highlighting how your renewed waste stream solutions are directly impacting and improving your bottom line.

Tried and true. Mechanical recycling is the “traditional” method of recycling: plastics are ground, cleaned, separated, dried, and compounded to produce new material.

Through advances in technology, more plastics than ever are able to be recycled. Utilizing advanced chemical recycling methods, we are able to reduce many plastic products back to their original molecular form. This method produces near-virgin quality plastics resins, thus greatly expanding its life cycle.

In our current economy, we take materials from the Earth, make products from them, and eventually throw them away as waste – the process is linear. Through industrial recycling services, we help businesses shift to a circular economy, where waste is minimized, and materials are reused to their fullest potential.

Eliminate waste and pollution

Circulate products and materials (at their highest value)

Regenerate nature

It is underpinned by a transition to renewable energy and materials. A circular economy decouples economic activity from the consumption of finite resources on our earth.