News

Closed Loop Partners Defines and Differentiates Molecular Recycling Terminology

Over the course of 18 months, Closed Loop Partners, an organization founded upon the shared goal of fostering a circular economy, conducted a study on molecular recycling technologies. Molecular recycling, commonly referred to as chemical or advanced recycling, includes a diverse set of technologies and definitions. Due to the diversity, there is often confusion between recycling methods or general misconceptions surrounding the processes.

The goal of Closed Loop Partners’ study was to differentiate between the various applications of molecular recycling technologies and to determine if these technologies can help us reach a more circular future for plastic waste. The study also addressed the financial viability of the different molecular recycling methods.

Types of Molecular Recycling

The first aim of the Closed Loop Partners study was to determine which recycling processes fall under the molecular recycling umbrella and how those are categorized. They found that there are three distinct recycling technology categories within molecular recycling. Those are purification, depolymerization, and conversion. They list their functions as follows:

- “Purification technologies can process electronic waste and films.”

- “Depolymerization technologies, which largely focus on PET and polyesters, are a critical recycling solution for synthetic textiles including carpets and athletic clothing.”

- “Conversion technologies like gasification can even take mixed waste, breaking down feedstock to basic carbon and hydrogen atoms.”

These three sectors of molecular recycling can further efforts of recycling plastic waste by processing and breaking down materials that are notoriously difficult to recycle mechanically. While both mechanical and molecular recycling have their place in the circular economy, the current capabilities of mechanical recycling leave a large portion of plastic waste in landfills. Molecular recycling technologies can help fill in those gaps.

Are Molecular Recycling Technologies Circular?

As a result of their study, Closed Loop Partners found molecular recycling “should only be considered circular when the supply chains produce a final product, which excludes fuel.” In other words, their study shows that while molecular recycling is indeed needed to further our efforts toward a fully circular economy through processing difficult plastics, it is by no means the final answer to sustainability problems. Molecular recycling should be viewed as complementary to mechanical recycling.

The Environmental & Financial Viability of Molecular Recycling

Closed Loop Partners’ study examined 9 molecular recycling processes in total to discover their environmental impact and financial viability. In their investigation, they discovered:

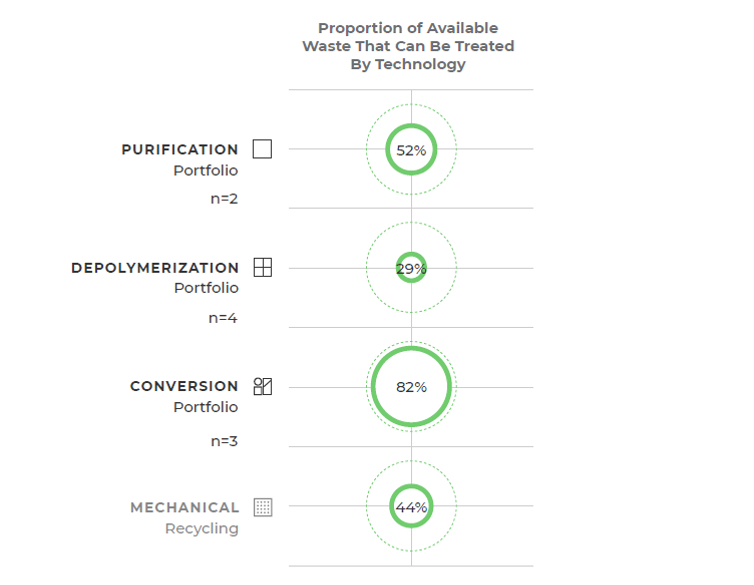

Conversion technologies are efficient. They found that conversion technologies could handle processing 82% of all the plastic packaging produced in the US and Canada. This number supersedes the capabilities of mechanical, purification, and depolymerization recycling.

Conversion technologies can process mixed plastics. While purification and depolymerization require single-resin feedstock that has been sorted, conversion technologies are able to process mixed plastics. Because of this capability, companies that utilize conversion technologies are sometimes paid to take mixed plastic waste instead of paying for it.

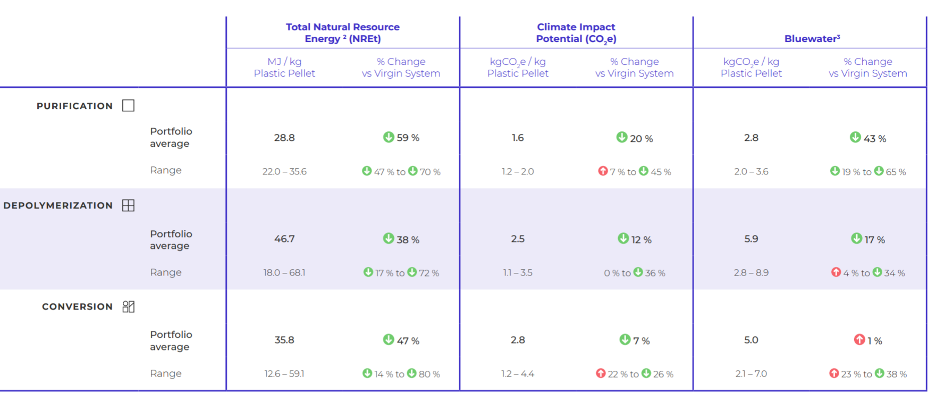

Purification is the most efficient molecular recycling process. When looking at how each recycling process handles reverting plastic back into usable materials, purification was found to be the most efficient. Through purification, 88% of plastic waste is fully processed and refined, whereas conversion technologies can only accomplish 42%.

Efficiency is key for reducing new plastic. The study showed that in order to more significantly reduce virgin plastic use, it is important for recycling technologies to be as efficient as possible.

Purification and depolymerization are better for the environment. These two technologies had a very similar footprint according to the study. The study examined energy use, water impacts, and greenhouse gas emissions, and these technologies produced less of an impact.

Most of the technology companies studied had a positive internal rate of return from these processes. Seven out of nine companies studied had a positive return on their feedstock investment in 2021. This is despite assuming they sell their recycled materials at regular market prices, without a premium.

Molecular Recycling Technologies Present Opportunities For Success

All in all, the Closed Loop Partners study found that molecular recycling can become an efficient, sustainable, and economical practice in the recycling industry under the right conditions. As a complementary application to traditional mechanical recycling, molecular recycling’s future is promising and presents opportunities for further reduction of plastic waste.

Closed Loop Partners acknowledges at the end of the study that “the molecular recycling sector is incredibly nuanced and diverse,” and that investors should be meticulous in researching various technologies prior to investing. However, they also recognize molecular recycling technologies are highly valuable for processing hard-to-recycle plastics and that through collaboration with consumer brands, policymakers, and investors, a “vision of success” can be developed for the molecular recycling sector.

iSustain Can Assist with Your Mechanical and Molecular Recycling Needs

This illuminating study by Closed Loop Partners showcases the advantages of molecular recycling in our modern world. By utilizing molecular and mechanical recycling processes, industries can seriously reduce their environmental impacts by diverting even more waste plastics from landfills. In doing so, they can also contribute to the circular economy and be a part of the movement towards a more sustainable future while also receiving revenue from their plastic feedstocks.

At iSustain, we make mechanical and advanced recycling simple. We specialize in helping businesses that have recyclables entering the waste stream, high waste management costs, or other waste challenges. Are you interested in finding out if advanced recycling technologies can help your business? Contact us today to learn more and see how we implement creative recycling for a changing world.