News

Plastic Recycling Processes

Understanding Plastic Recycling Processes and Their Impact

Plastic waste is everywhere. From the wrappers around our food to the packaging that ships products to our door, it’s an unavoidable part of modern life. But what happens when plastic has served its purpose?

At iSustain, we’ve spent years working with recyclers, both mechanical and advanced, to give plastics a second life. We’ve witnessed the various processes used and expanded our knowledge of recycling technology along the way. While the terminology and industry jargon can often be confusing, we’re here to demystify plastic recycling processes, explain how they work, and show the real-world impact they can have. Whether you’re managing waste for your business or simply curious, let’s dive in.

Why Traditional Recycling Isn’t a One-Size-Fits-All Solution

You’ve probably heard the term “reduce, reuse, recycle.” It’s a great mantra, but it doesn’t capture the complexity of the recycling process. Plastics come in a variety of types, from simple PET bottles to complex multi-layered packaging, and not all of them are easy to recycle. For example:

- Mechanical recycling handles straightforward plastics like water bottles but struggles with contaminated or degraded materials.

- Advanced recycling takes on the harder-to-recycle plastics by breaking them down into their molecular building blocks.

Together, these processes create a system that maximizes the potential of plastic waste, transforming it into new products, materials, or even energy. Globally, only about 9–10% of plastic waste is effectively recycled, which is why multiple solutions are needed (OECD).

Plastic Recycling Processes Explained

Mechanical Recycling: How It Works and Where It Fits

When you hear the term “recycling,” mechanical recycling is likely the process that comes to mind. In mechanical recycling, plastics are reshaped into new products without changing their polymer structure.

- How It Works: Plastics are cleaned, sorted by type, shredded, melted, and remolded into new items. This aligns with the collect–process–remanufacture model used across U.S. recycling systems (EPA).

- End Products: Items like stretch film, trash bags, park benches, or car parts.

- Challenges: Plastics can lose quality over time due to contamination or repeated heat exposure, which limits reusability. Mixed materials or contamination also pose challenges.

- Examples: Sigma Stretch Film is driving the circularity of LDPE films by incorporating recycled LDPE into their stretch film products. iSustain partners with Sigma to recover used stretch film to mechanically recycle it and incorporate into PCR-containing film products. See how it works.

What Is Advanced Recycling?

In advanced recycling, plastics are broken down into their molecular components so they can be reformed into new resins. The process involves proven chemical routes to recover plastic building blocks. EPA describes these solution pathways broadly under solvolysis and related methods such as methanolysis and glycolysis (EPA).

Depolymerization

This process breaks plastics down into their molecular building blocks, called monomers.

- How It Works: Techniques like dissolution, enzymolysis, or thermal and chemical depolymerization reverse polymerization.

- End Products: High-quality monomers that can create food-safe packaging, medical supplies, or high-performance plastics for industrial use.

- Example: Loop Industries uses low-temperature methanolysis to recycle PET waste, such as plastic bottles and polyester fibers, into monomers like dimethyl terephthalate (DMT) and monoethylene glycol (MEG), which are reassembled into new PET.

Conversion Processes

This approach transforms plastics into entirely new materials or energy.

- How It Works:

- Pyrolysis: Converts plastics into oils and fuels.

- Gasification: Produces syngas, a mix of hydrogen and carbon monoxide, used for energy or manufacturing.

- Energy Recovery: Burns certain non-recyclable plastics to generate heat or electricity, often with emissions capture.

- End Products: Fuels, raw chemicals, or energy for industrial processes.

- Example: iSustain’s alternative energy solutions demonstrate conversion in action. By partnering with kiln co-processing facilities, iSustain helps divert non-recyclable plastics and other materials from landfills, turning them into energy sources for cement production. This reduces fossil fuel use, supports circularity, and avoids methane emissions from decomposing landfill waste.

Why These Processes Matter

Plastic recycling processes play a critical role in tackling the growing challenge of plastic waste. Each method, whether mechanical or advanced, has a unique contribution to make, shaping the way we manage materials that would otherwise end up in landfills or as pollution in the environment.

Mechanical recycling is often the first step. By reprocessing items like bottles and containers, mechanical recycling extends the life of plastics in a straightforward way, turning waste into usable products. However, mechanical recycling has its limits. Over time, plastics can degrade, becoming less suitable for reuse. Additionally, contaminated or complex plastics, such as multi-layered packaging, can’t always be processed through this method.

Advanced recycling provides solutions for more challenging plastics. By breaking plastic waste materials down into their molecular components, advanced recycling processes create new possibilities. Pyrolysis converts plastics into oils that can serve as feedstock for manufacturing, while gasification produces syngas, a versatile energy source. Depolymerization takes plastics back to their original building blocks, enabling the creation of high-quality materials for applications like food-safe packaging or medical supplies (Loop Industries).

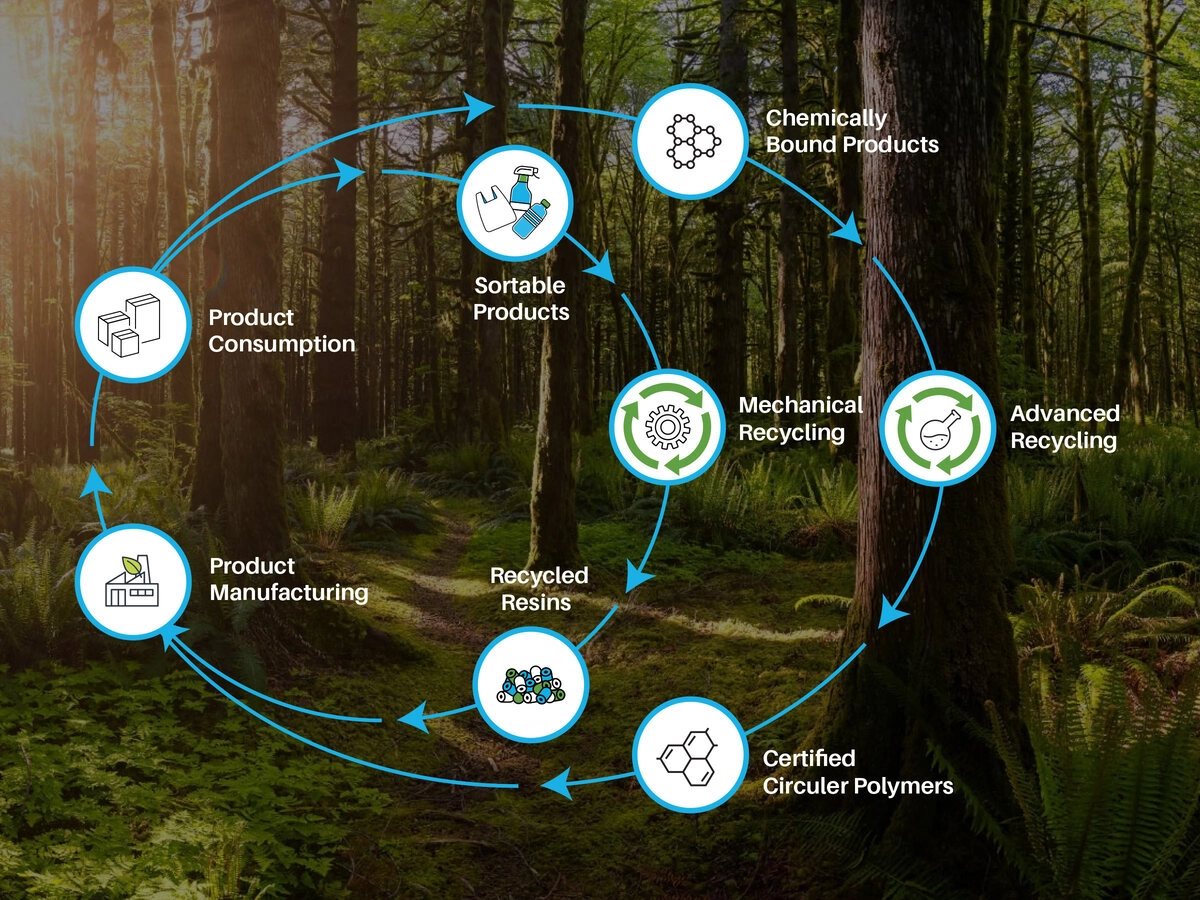

The importance of these methods extends beyond waste reduction. They support a circular economy by reclaiming resources that would otherwise be lost. Economically, recycled plastics reduce reliance on virgin materials, offer cost-effective alternatives, and create opportunities for innovation. From the everyday products we use to the energy that powers industries, recycling processes show that plastic waste doesn’t have to be an endpoint, it can be a starting point.

Recycling Is a Resource

Plastic waste doesn’t have to be a dead end. Through a combination of mechanical and advanced recycling processes, waste plastics can be transformed into something new, whether that’s a product, material, or energy source. By understanding the plastic recycling process, we can all play a role in making more informed, sustainable decisions. For system context and definitions around collection, processing, and remanufacturing, see the EPA’s overview of the U.S. recycling system (EPA).

To learn more about iSustain’s work in recycling and our various partnerships with mechanical and advanced recyclers, visit our Partnerships page.